Monday, 6 December 2010

Tuesday, 30 November 2010

duckets done

Monday, 29 November 2010

curly!

Finally, having checked photos of the real thing, I binned the truss rods in the kit (far too chunky and square section) and made some better circular section ones from wire myself.

Now I need to add kleenex tissues to the roof (yes really) and attach the duckets. This requires soaking thin plywood in hot water to shape it - ummm sounds fiddly! My practice attempt was ok but the top of the ducket has a very tight bend to form Might be easier in brass, but then I would still have to add the plywood overlay to that. Thinking cap on...!

Sunday, 28 November 2010

brakes off...

Here is the current state of construction - sides, ends and floor all glued together and roof supports glued in (the elastic bands are to hold it all square whilst it dries). Next come the beautiful overlays all made from laser cut plywood. Very impressive.

The bogies are already complete too.

Monday, 26 April 2010

Earthworks update

As you can see below, much earth has been imported to the back garden from a project in the front garden. Today I laid out a circle of track to work out how wide this earthwork would need to be to accommodate the loop back on itself. The answer is about 1.8m.

Sunday, 25 April 2010

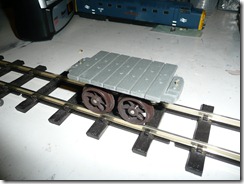

Bogies for the Gladstone

I wanted to add the bogies (and couplings in time) to the Gladstone so it can be ready for gauging and power trials once the garden earthworks are completed. Thus with a bit of drilling, countersinking and screwing tonight we have one carriage with wheels!

Monday, 12 April 2010

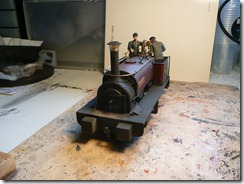

16mm show - the debut of Rough Pup

http://www.youtube.com/watch?v=QNivf5k10_M

A great time was had by all (show report coming soon) and Rough Pup performed well.

Monday, 29 March 2010

A quick waggon kit

There has been much DIY going on recently in the ‘new’ house so modelling has been difficult. Tomorrow we have a new boiler and bathroom going in so I can’t see any change in that situation. But I did manage to find 10 mins to make up this little beastie – an andel models slate slab waggon. A piece of slate will be added on top once it’s painted. Nice and simple and it runs beautifully.

Thursday, 25 March 2010

Coupled and ready to go

I have now completed the electrical and mechanical links between loco and wagon. The couplings are simple chain links and the electrical connector is of the futaba type and is relatively unobtrusive.

My wife says that the wagon looks like it’s got a bomb in it! This will be covered by a tarpaulin.

The only other bits that are necessary to complete before the show are to attach the nuts on the end of the big end with retaining compound as they keep working loose and to add some brasso to the slidebars to ensure they run nicely.

Friday, 12 March 2010

Done!

Just in time for the family to inspect tomorrow… The motor needs it’s electrical connector to the accompanying wagon soldering on and the wagon still needs some work, but the loco is basically complete.

I have had second thoughts on the bucket as I believe it to be a bit out of scale when comparing it with shots of a similar engine with bucket on this site http://www.penmorfa.com/Slate/Dinorwic-1967-4.htm

Tuesday, 9 March 2010

A bit of progress

- To attach the main blower pipe (copper) between the smokebox side and the cab

- To cut to length 4 copper pipes to be installed on the backhead

- Added weathering powders around the smokebox door and cab floor

- Added rust dry brushed onto the filler cap and smokebox rivets

- Touched up a few areas such as the handrails

Nearly there now!

Monday, 8 March 2010

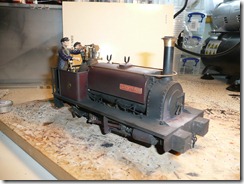

Reassembled

Here we are after an hour of painstaking reassembly tonight. It is incredible how a paint thickness of a few microns can cause parts to stop fitting as they did – the handrail had to be stripped back to brass to get in in and the firebox didn’t fit into the boiler without fettling too. The motion is all connected up and the motor reinstalled – not without having to resort to using superglue on a screwdriver to get the screws back in!

The handrail and brake gear cross rods are now glued in.

What remains to be done?

- Install nameplates

- Touch up areas where paint has got knocked/missed.

- Glue in driver/fireman/bunker false floor/bucket (add sand into bucket too)

- Add coal to bunker bottom hatch, rust to rivets and possibly some water stains near the filler hatch. Add weathering powders around cab floor and smokebox door.

- Reinstall rear coupling (had to be removed to get larger motor in/out)

- Install buffers on accompanying wagon at same height as loco and add couplings for that wagon (fabricated tonight ready).

- Install power coupling between loco and wagon

- Design some kind of tarpaulin for accompanying wagon (painted bacofoil?)

- Add copper pipework to loco between smokebox and cab and at bottom of gauge glasses.

- test loco and then fix 10ba nuts on big end with retainer in the thread

- Find a suitable box for storage/transport.

- Attend Stoneleigh show.

Progress update

As you can see above further digging around the garden planting various shrubs and bulbs has created a large pile of clay. This has been placed such that it can be moulded into an embankment at the far end and will include a loop around so that continuous running is possible. The point will be sprung – I must read up on how to do this!

and work has not stopped on Rough Pup either. Below you can see the major parts prior to reassembly.

Work has included:

- Weathering the driver and fireman.

- Weathering the brass handrail.

- Working out where the copper pipe runs go.

- Weathering the firebox to match the rest of the engine and dirtying up the brass safety valves (but not the whistle) as shown in many photos of the engines at work.

- Painting the nameplates red and then distressing them.

- Painting the hornguides and then weathering them.

- Freeing the slidebars from the inevitable sticking after weathering.

- Drilling two small holes in the rear buffer beam to allow the motor leads to nicely travel across to the running wagon.

- Weathering the running wagon to match.

- Soldering together the radio control circuitry (except the motor which will need to be installed in the engine first. This is shown below.

- Building a false floor for the coal bunker and glueing coal on top of it.

- Preparing for reassembly of the loco.

So, the next step is reassembly followed by some dry brushing to add rust and weathering powders for texture. Note the expanded polystyrene blob below which will be used for adding random textures of powder.

Saturday, 6 March 2010

Foundations and a bucket

Friday, 5 March 2010

Oh my word

Progress:

- buffer beams and rods painted red (3 times)

- buffers painted natural wood colour and the dry brushed with black and grime colours

- whole model airbrushed using a mix of black and railmatch frame grime.

I’m absolutely gobsmacked that I have built and painted this – it’s ridiculous how on earth have I managed it?

Further progress

So here she is temporarily kind of posed so you can see the livery U have chosen. This is meant to be a dirty quarry engine and so nothing about the paintwork is meant to be perfect. Which is a clever way of hiding mistakes too :-)

The dull LMS crimson lake was airbrushed at 1:1 and done in such a way that the black underneath kind of still shows through, making it look like the paintwork is grubby. I am really pleased with this. Further weathering and rusting around the filler cap will be done and the handrail knobs and fire iron brackets will be painted black again. The cylinders were brushed and one coat nicely shows through the black. However cleaning out the airbrush took ages – I officially hate enamel paints.

Weathering has now commenced using acrylics (hooray no enamels here) and here is one illustration of the effects I’m after – peeling paintwork and a bit of rust. The effect will be dulled down with general weathering. Sorry the photo is slightly out of focus.

Note the rods have been painted with humbrol “buffer beam red” but despite much mixing these are in fact pink(!) so railmatch BR crimson will be used over the top and should improve the hue! How humbrol, think that is buffer beam red I don’t know.

I have also sorted the plates out with a red partly peeling backing) and these will soon be installed. In fact it won’t be long before I put the engine back together and then add the copper pipework.

It might even be ready for Stoneleigh.

De Winton rods

have arrived – check out these bad boys in nickel silver. Mega thanks to Dave Andrews for etching them up for me.

Thursday, 4 March 2010

Disaster, recovery and the plan

I started spraying the boiler/tank/smokebox assembly and this is what happened! The other side was great. damn!

So I stripped all the paint off using cellulose thinners (smelly stuff!) and then used a fibreglass brush on this area…I tried again and hey presto… it’s fine. Two coats have been applied.

Then the chassis was sprayed matt black too. One footplate has also had some acryllic black (slightly browny) dry brushed on to give a kind of oily appearance. This is a test to see what it looks like. It will be airbrushed over anyway but I hate uniform colours like the matt black which is not true to life. Real footplates have oily mank on them, so mine will too. Here they are drying for the night.

The plan is to use the tamiya masking tape pictured to mask off the panels and then airbrush on the phoenix crimson lake (dull) using airbrush thinner from railmatch (Ian Rathbone says normal white spirit is just as good, but I had already bought this so why not give it a go). The buffer beams and rods (once they have been brush primed) will be bright red (humbrol enamel probably but maybe acryllic I haven’t decided yet).

Primed!

and here is the chassis primed. The propagator gives you some idea of the size of the extractor. It looks good (I can only see one stray fibreglass piece), but even after drying with a hairdryer I’m going to leave it a while before I start the next coat!

The good news is that the slidebars still slide! cool!

Ready for primer

So after much brushing and cleaning I rubbed shiny sinks on the chassis which got rid of much of the tarnish and then rubbed vim onto it to neutralise. After a while drying I went to have a look (half time in the England match) and a few areas had gone green – this is where the vim had attacked flux deposits. These were rubbed off and the model washed again. A few water stains were then removed and one piece of the inside valve gear required re-soldering. A final clean around that and we’re ready to go.

I have decided to prime the bottom first as if there are any major problems they shouldn’t show up. I have used some heat shrink tubing to cover the connecting rods and will mask off the piston rods with masking tape.

Fingers crossed!

Wednesday, 3 March 2010

Cleaning up, ready for painting

April 10th is the National Garden Railway Show and 16mm association AGM at Stoneleigh Warwickshire. As part of this event the planners are hoping for 101 Hunslets to be on show alongside the star attraction – the newly restored Edward Sholto, previously of Penrhyn Quarries and latterly stored in the USA.

My Rough Pup is registered to attend and although it could do so in current condition, it would be far nicer to have it there painted.

Thus prep work started last night with the boiler/smokebox lifted off, the already painted firebox removed and the motor, gears and wheels lifted out.

Now its time to clean her up. My weapons of choice are shown above:

- Fibreglass brushes of 2,4,8 and 10mm for cleaning up, giving the brass a key for the paint to adhere to and general surface improvement (removing solder etc)

- A chisel scapel and screwdriver to remove blobs of solder

- A brass brush, cosmetics brush, paintbrush, toothbrush and foam brush for getting into corners and washing cleaning stuff around.

- Acid cleaners – shiny sinks (cream) and viakal to really buff up the brass plus acetone (cheap nail varnish remover) to use sparingly oN really grubby bits.

- Alkaline cleaner VIM to remove flux deposits.

- I will also use the airbrush to blow away any water that gets under laminations etc and also get rid of those pesky fibreglass bristles.

The plan is as follows:

- Clean up with fibreglass brushes etc

- buff up brass with acid cleaner

- neutralise with alkaline cleaner

- wash thoroughly with water and let dry overnight

- use airbrush to finalise drying.

- mask off slidebars and connecting rods

- prime with halfords car primer (red oxide as paint on top of it could later be rubbed down to reveal this as rust).

- airbrush chassis black.

- airbrush sides and back red.

- mask off brass details on boiler/tank and prime brass boiler grey, paint resin directly red (no primer required).

- Line out, add nameplates

- Weather using airbrush and t-cut.

and all before April 10th.

Oh and at some point finish the electrical connection and couplings to the running wagon, install battery/ESC and Rx and cover with tarpaulin!

Sunday, 28 February 2010

Test track

Saturday morning was spent clearing parts of the garden where the railway will go (bye bye huge hebe and a few other assorted plants plus most of a green wire fence).

Later it was raining outside, so we decided to try putting together some track to get an idea of the space we’ll need and how wide the concrete foundations will need to be. As can be seen above the design of peco points leaves a little to be desired when you want to attach plain track onto the diverging ends! But we made do for now.

The kids had great fun zipping waggons along the track.

It also allowed me to check all my waggons’ back to back measurements.

Fun was had by all.

Friday, 26 February 2010

Skipping along

One binnie skip wagon made up. A great kit, easy to put together and very nicely designed. I will get more.

Wednesday, 24 February 2010

16mm association

The latest edition of the 16mm magazine arrived today along with a CD containing a load of videos of 16mm garden layouts in action – wonderful.

Given that it is £17 for a year (4 issues of this high quality mag) plus extras like the free book they gave out this year too, I have to say that the 16mm association puts the 009 society in the shade somewhat.

Monday, 15 February 2010

Slate quarry office

Monday, 8 February 2010

De Winton rods

Thursday, 4 February 2010

Gladstone

The cant rails and end top pieces have now been attached. These are not perfect, but frankly it is impossible to get them perfect given the fact that the cant rail supplied was bent all over the place. However I am generally pleased. The next step is to cut and install thin pieces around all the window openings for strength and to provide a lip for glazing. and yes you’ve guessed it, these are not pre cut for you – another very time consuming job ahead!

Monday, 1 February 2010

Gladstone comparison

Friday, 29 January 2010

Gladstone and RC update

Firstly the Gladstone:

- The rest of the seat sides have been put together and stored ready for the slats to be added.

- The internal partitions have had their windows filed square (they were cut out with curved edges!

- The sides and ends have been glued together to form a box as below and clamped with anything I could find whilst they glued.

Also some good news on radio control. Having given up on the viper, I decided to pick up a cheap (and smaller) unit on ebay. It works!!

My chosen system is a 2.4Ghz transmitter and receiver from planet 5, a 12v 3300mAh battery pack and this ebay ESC.